Electron beam welding is used for joining metallic materials with normal welding seam depths. The very thin weld seam and its narrow heat affected zones drastically minimises the energy transferred and the distortion to the component as whole. Components that have a tendency to distort and subassemblies that require a high level of mechanical pre-processing can be joined using this method without being damaged.

Principle

Electrons are created in an EB generator by emission and accelerated in the vacuum using high voltage (up to 150 kV and above). The generator is mounted to the processing chamber with the work piece inside. The chamber has to be evacuated. To make a weld, the electrons are focused on the point of the seam. Normally the components are welded without filler materials.

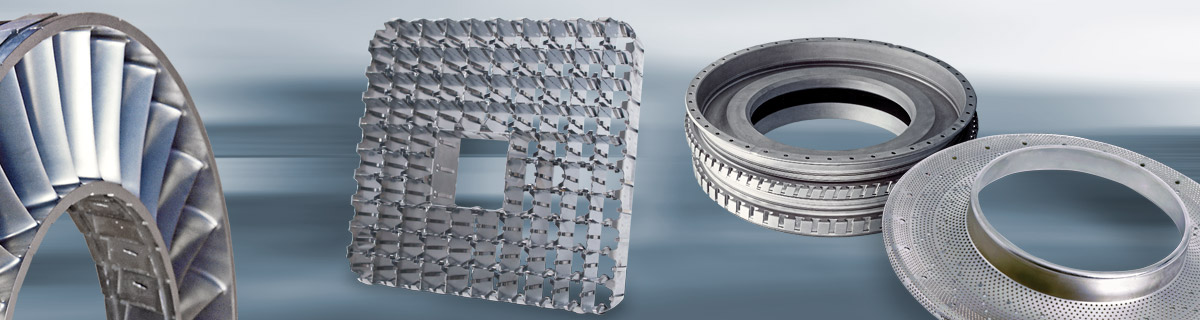

Various types of weld are distinguished depending on the basic geometric shape of the components requiring welding:

- Radial weld

- Axial weld

- Weld seam on plane work pieces

- Curved/free form

Where the weld can be made continuous, discontinuous or as a spot weld.

The main application areas are:

- Automotive

- Machine construction

- Medical technology

- Aerospace

- Power engineering

- Vacuum technology

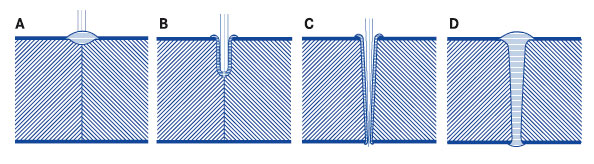

Deep welding effect

- The high energy concentration at the beam spot melts the material.

- Material vaporises in the centre.

- The beam penetrates deeper into the work piece through the vapor channel which is formed.

- As the work piece is moved melted material flows from front to back, around the vapor channel, and solidifies.

EB welddepth calculator

Usage:

Fill in the form beginning from top. Select your high voltage level and beam current. Beam power will be calculated. By providing a velocity, the track energie can be calculated. With the selected material the aproximated welding depth is shown. When entering a depth value, the track energy and beam power are calculated. The beam current can be determined by the beam power.

Please enter the data here:

Bimetallic Joints: Weldability

| Ag | Al | Au | Be | Cd | Co | Cr | Cu | Fe | Mg | Mn | Mo | Nb | Ni | Pb | Pt | Re | Sn | Ta | Ti | V | W | Zr | |

| AG Silver | C | S | C | D | C | C | D | C | D | N | C | C | S | D | C | C | D | D | |||||

| Al Aluminum | C | C | C | C | C | N | C | ||||||||||||||||

| Au Gold | S | C | D | S | C | C | N | S | S | N | N | D | N | ||||||||||

| Be Berylium | C | N | N | D | D | ||||||||||||||||||

| Cd Cadmium | C | N | D | D | D | S | D | N | N | D | C | N | C | N | N | N | D | ||||||

| Co Cobalt | D | C | D | C | C | C | C | S | C | S | S | ||||||||||||

| Cr Chrom | C | D | D | C | C | C | C | S | C | C | C | S | C | S | D | S | |||||||

| Cu Copper | C | C | S | C | C | C | S | D | C | S | C | S | D | C | D | D | D | ||||||

| Fe Iron | D | C | D | C | C | C | D | C | C | C | C | S | S | ||||||||||

| Mg Magnesium | C | S | D | D | N | N | N | D | N | D | D | ||||||||||||

| Mn Manganese | C | D | C | C | S | C | D | C | N | D | |||||||||||||

| Mo Molybdenum | D | C | N | S | D | C | S | D | C | D | S | S | S | S | |||||||||

| Nb Niobium | N | N | N | C | N | S | N | S | S | S | S | S | |||||||||||

| Ni Nickel | C | S | D | S | C | S | C | C | S | D | |||||||||||||

| Pb Lead | C | C | N | C | C | C | C | C | C | D | N | C | N | C | N | N | D | ||||||

| Pt Platinum | S | S | S | C | S | S | C | S | C | S | |||||||||||||

| Re Rhenium | D | N | N | N | S | S | D | N | N | D | N | C | D | D | |||||||||

| Sn Tin | C | C | D | C | C | C | D | C | D | D | |||||||||||||

| Ta Tantalum | N | D | N | D | N | S | S | N | S | S | C | ||||||||||||

| Ti Titanium | C | S | D | S | S | S | S | C | S | ||||||||||||||

| V Vanadium | D | D | N | D | D | S | N | S | S | N | D | S | S | ||||||||||

| W Tungsten | D | N | N | S | D | D | D | S | S | D | S | D | S | C | S | ||||||||

| Zr Zircon | D | D | S | C | S |

Excerpt of exemplary material combinations

Legend

empty = Intermetallic compounds formed – undesirable combination

D = Insufficient data for proper evaluation – use with caution!

N = No data available – use with extreme caution!

S = Solid solubility exists in all alloy combinations – very desirable combination

C = Complex structures may exist – probably acceptable combination

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano