A new era at SwissBeam AG!

Project of the month — April 2020

A new chapter in the history of SwissBeam AG is being opened with the acquisition of a new, valuable electron beam welding system.

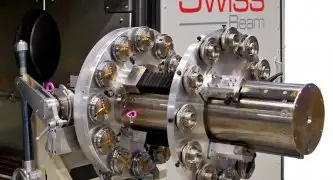

Precision, accuracy and perfection are always the cornerstones of our daily work. Last month, we were able to put a new electron beam welding system into operation at our factory workshop. The processing spectrum ranges from the smallest parts of 0.1 mm thin films to components with a length of 2,560 mm. The system is suited to welding single parts up to large-scale production and is equipped with quick and easy programming, which can be carried out straight from the office. Setup and processing ensure the best possible cost, quality and service with quick response times.

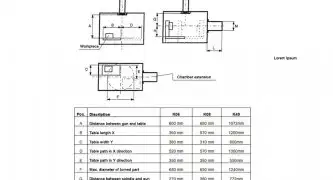

Key technical features of the new K49 electron beam welding system from Steigerwald:

| Beam power | 0 – 15 KW |

| High voltage | 70 – 150 KV |

| Beam current | 0 – 100 mA |

| Working distance | 200 – 1`500 mm |

| Table dimensions x, y | x = 1`280 mm, y = 600 mm, z = 400 mm |

| Travel path in | x = 1`220 mm, y = 550 mm |

| Speed x, y | 1.0 – 100 mm/s |

| Table load | 1`500 daN |

One special feature is the newly developed “fast beam deflection” with the name EBO Jump. This technology enables electron optical imaging, automatic beam adjustment, online seam tracking and multipool technology. The video shows an electron beam welding process using multi-beam technology. The two leading beams preheat the workpiece (on the right and left side of the seam). This is followed by the actual welding process with a small spot size and deep penetration. The subsequent melting process produces a cosmetic seam with a wider spot size and lower energy input. The dynamic vectorization is easy to see in the beam deflection pattern. It ensures that the individual processes are aligned perfectly with the welding path, in spite of their spatial separation. Even less visible, but still crucial, is the optimized focus position of the electron beam for each process. Preheating, welding and cosmetic processes each have their own focus setting, thanks to the use of a fast focusing lens. The two preheating zones have different power settings due to having their own, different material properties.

We were very satisfied with the services provided by the machine manufacturer throughout this process, from purchasing the system to its installation. The goal-oriented system planning, as well as the pleasant and constructive manner of communication, deserve special mention. Setup and commissioning were carried out without any complications. We highly recommend the machine manufacturer, Steigerwald, from Maisach (near Munich)!

SwissBeam is proud of its newly commissioned electron beam welding machine and the resulting increase in welding technology competences. Another highlight for us is the fact that we have been able to create additional capacity, which allows us to meet customer requirements in an even more targeted manner.

Please feel free to contact us with your own inquiry at: info@swissbeam.ch

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano