Precise and fast: Drilling with the Electron Beam

Steigerwald Strahltechnik Sets Standards with Machines for Microdrilling Technology

The electron beam drilling technology (also known as EB perforation) developed by Steigerwald Strahltechnik GmbH (SST) has become one of the leading methods for micro drilling applications. With cutting-edge technology and innovative processes, the company sets new benchmarks in precision, efficiency, and reproducibility - essential qualities for demanding manufacturing tasks in industries such as recycling, construction, and paper production.

Precision Through Focused Energy

The unique feature of this method is the high-power density of the electron beam, reaching up to 10⁸ W/cm². The beam creates a keyhole surrounded by a molten sheath. This keyhole enables deep, precise drilling - even in hard-to-machine materials such as titanium, nickel-based alloys, or other thermally resistant materials. The resulting hole is slightly conical, which is particularly advantageous for filters as it prevents clogging.

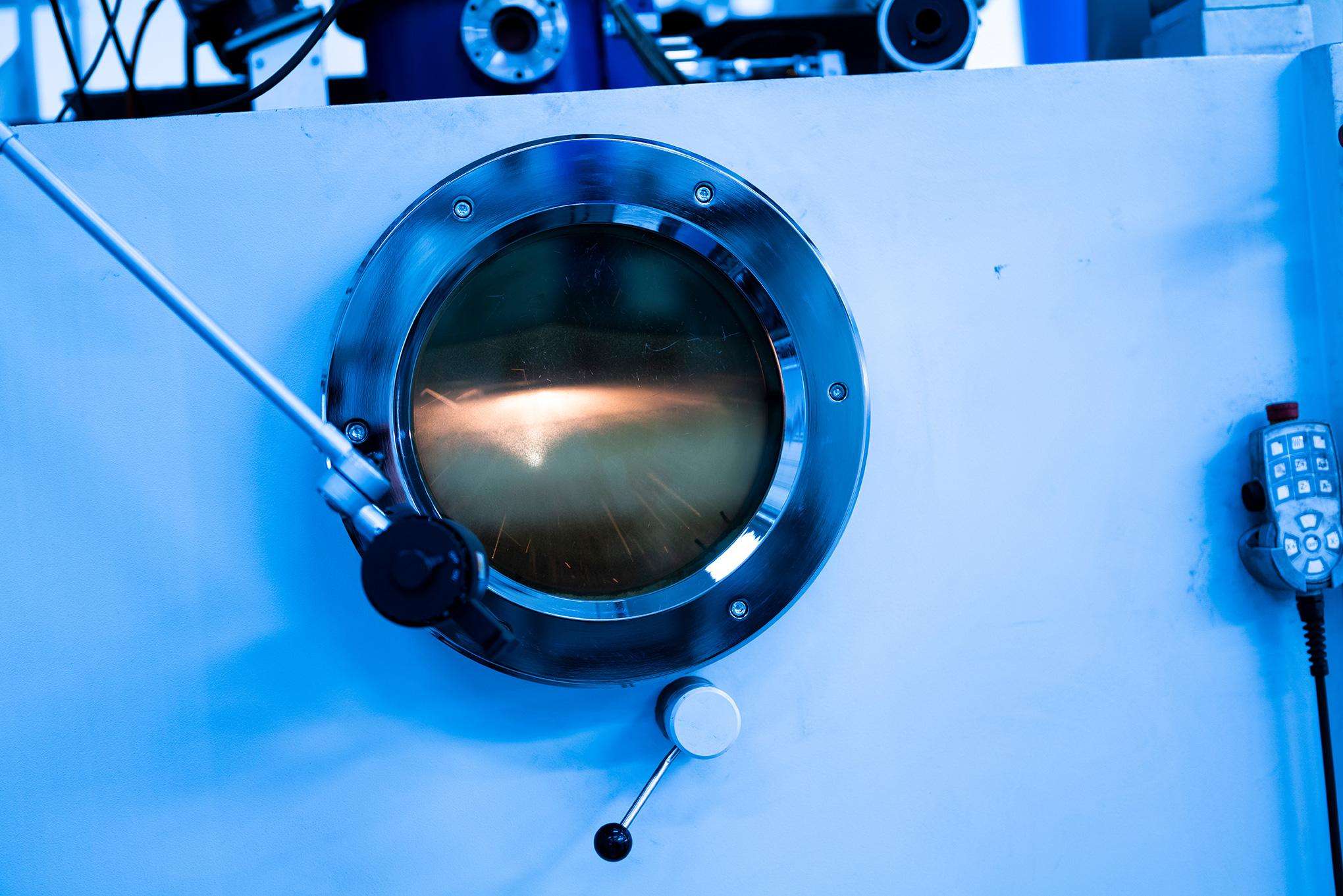

Abbildung:

The electron beam during the drilling process.

© Fig.: Steigerwald Strahltechnik GmbH

Efficiency Redefined: „Drilling on the fly“

One of SST's groundbreaking innovations is the "Drilling on the fly" process. Here, the electron beam is guided synchronously with the workpiece movement, and the beam is briefly switched off between holes to position itself for the next drilling point. This method allows for extraordinarily high drilling frequencies, outperforming other technologies such as laser beam, EDM, or ECM in terms of speed and efficiency. Drilling or perforating with the electron beam is a high-speed process capable of achieving drilling frequencies of up to 3,000 holes per second. Sheets up to 7 mm thick can be processed, with hole sizes ranging from 30 µm to 1.2 mm..

Consistent Quality and Reproducibility for Diverse Applications

The electron beam is controlled entirely electromagnetically, enabling all parameters to be precisely stored and reproduced at any time. This ensures consistently high quality in series production - a decisive advantage over mechanical machining methods. These features make electron beam drilling the top choice for applications demanding the highest standards in quality and surface finish. Examples include filter manufacturing, recycling, paper production, the food industry, and construction, where it is used, among other things, to produce insulation materials.

EB Drilling in contract manufacturing

If investing in machine technology is not in line with your philosophy, we are happy to offer you development work and reliable contract manufacturing at our sister company PTR Strahltechnik GmbH in Langenselbold.

Conclusion: Electron Beam Technology by SST as a Solution for the Future

With solutions like "Drilling on the fly" and precise electron beam control, Steigerwald Strahltechnik sets new benchmarks in micro drilling technology.

Thanks to its versatility in terms of materials and applications, SST's technology is an indispensable tool for many industries. The combination of precision, efficiency, and innovation makes SST a world-leading provider of electron beam technology - and an important partner for the manufacturing industry of the future.

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano