EBOCONT strip welding machine

successfully put into service at Wieland Werke AG in Ulm, Germany

Wieland is the world’s leading specialist for copper and copper alloys. The Group has many locations on a number of continents, enabling them to supply customers around the globe with their semi-finished products.

The Ulm location decided to use electron beam technology from Steigerwald Strahltechnik (SST) to further enhance its capacities in the field of tri-metal strips. During the first quarter of 2021, SST delivered an EBOCONT electron beam strip welding machine to the plant.

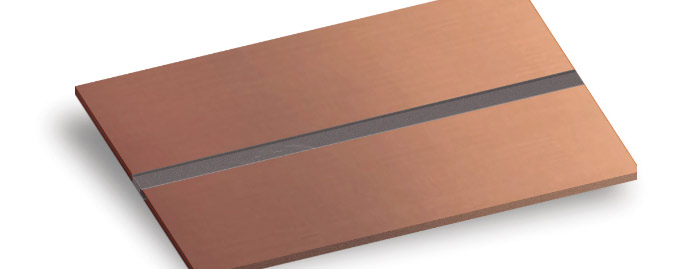

With this continuous pass system, it is now possible to weld three individual strips of copper and copper alloys with equal or different thicknesses into a tri-metal strip using an electron beam. Wieland Werke AG decided to acquire another new machine of this type in order to address the increased worldwide demand for precision resistors. These so-called shunts are used, for example, in battery management systems in the field of electromobility, and in smartphones.

Also, the conversion from magnetic to electronic energy meters in most European countries has resulted in a significant rise in demand for modern measuring technologies.

Tri-metal copper strip made of three individual strips

Shunt made from a tri-metal strip (Source: Wieland Werke AG, http://www.wieland.com)

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano